Our intention is to add silicone diff oil to be able to easily tune the diffs. Yes, it is possible and quite easy. But what you want to achieve will dictate the parts you will use.

I’ve actually tried this a couple of months ago, modifying the early LA-1 casing so that the rere OT-224 differential output shafts and the bearings would fit. This requires grinding down the LA-1 diff in two places: the tube part where the outdrive goes through and the little bevel on which the bearings sit. If you can do this on a lathe, you can be quite precise, but the end result will always be a diff that is around 1.5mm too narrow and that will float in the gearboxes.

But as it turns out, Kyosho has made 3 versions of the LA-1 diff casing.

Left: the original LA-1. Notice there is no recess for an o-ring around the output shafts

Middle: revised version with o-ring

Right: latest revised ’15-0083′ marked version

You will need the latest 15-0083 version of the casing for inserting the OT-224 shafts. The other versions will not allow the pin to be inserted into the shafts as the hole in the shaft doesn’t enter the inside of the casing enough.

These are the parts you’ll need:

- LA-1 differential casings marked 15-0083

- OT-222 differential internals

- OT-224 outdrive shafts

- ORG-045S o-rings

- Preferably some thread sealer tape, like Loctite 55

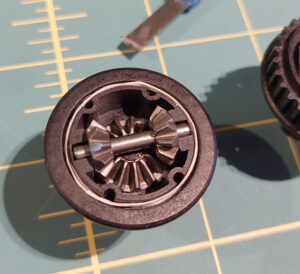

Mount the bearings on the casing first, insert the o-ring (I always use some Team Associated ‘green slime’ on any o-rings), then insert the drive shafts into the differential housing. Locate the little pin into the hole. Do NOT use the provided metal 0.15mm washers, because this will make your diff way too tight and lock the gears onto each other, preventing them from turning.

Insert the gears and place a correctly cut string of teflon tape (white ‘string’ in the picture) in the recess of the gear diff.

Add silicone diff oil to the part where you placed the teflon tape. Fill to the top. Then place the other side onto this assembly.

PS – you may want to put some of the diff oil behind the large gear of the other diff half, to make sure it doesn’t drop off when assembling both halves.

LA-1 with OT-28 and OT-5 parts at the top, LA-1 with OT-222 and OT-224 parts at the bottom.

What it solves, what I like and what I don’t like

You may have experienced the older OT-28 parts breaking or the gear coming off the shaft. The early versions were friction pressed onto the shaft. It also can create tension on the gears and over my lifetime I have found one gear cracked after a big jump, probably the dogbone crashing into the diff. Later OT-28 versions however have the gears located with a small bolt which eliminated the issue.

And the OT-5 cups are fitted with a grub screw so they may come loose if you didn’t tighten them properly and used thread lock.

But maybe you can’t find the OT-28 parts anymore. Then yes, fitting the rere parts will get your car running again.

For me, the main drawback is the construction as a whole. The outdrives are shorter, so your dogbones may pop out sooner than with the OT-5 drive cups. And there is no way you can remove the OT-224 outdrives (eg. to fit new ball bearings) without completely disassembling your diff.

In all honesty, I don’t like the tinkering with silicone oil on these parts as it’s just so easy to contaminate the belt pulley with it. Some mineral spirits can clean the oil up however.

Conclusion

After testing with the rere parts, if I wanted to use diff oil then I’d just stick to the OT-28 parts in the late version LA-1 casing. The gears are strong enough, they keep the diff and bearings easy to work on, you can fit the o-rings and the teflon tape, just make sure the OT-5 cups are tightened well. You can even add or remove washers to move the outdrives in or out.

So I’m not really convinced this mod is always worth the while.