The Kyosho LA-1 bag includes 4 parts

- an outside ‘bell end’ part

- a pulley flange (keeping the belt on the toothed pulley part)

- 1 toothed pulley part for a geared diff (using OT-28 parts originally)

- 1 toothed pulley part for a ball diff (slotted part, which can house the diff balls)

The pulley accepts belts 4mm wide with a 3mm pitch (S3M type).

The case accepts 8 x 14 bearings to fit the Lazer setup (LA-1 / OT-5 / standard gearboxes).

Experiences or weaknesses

The diff case halves use small M2.6 screws to hold them together. It is relatively easy to strip the thread and you may want to drill out the holes slightly to use suitably larger M3 screws. Depending on the head size they might sit a bit proud of the casing, so check your specific setup to see if they won’t hit the gearbox walls. While this will increase the rotational weight slightly, it will hold everything together without any issues.

The casings are not really meant to use diff oils. Although it is possible to use eg. PTFE (Teflon) tape rolled up in the channel as a gasket, or carefully cut a gasket to size, the leakage will mainly be around the outdrives. The LA-1 variants discussed below may improve this.

Revisions

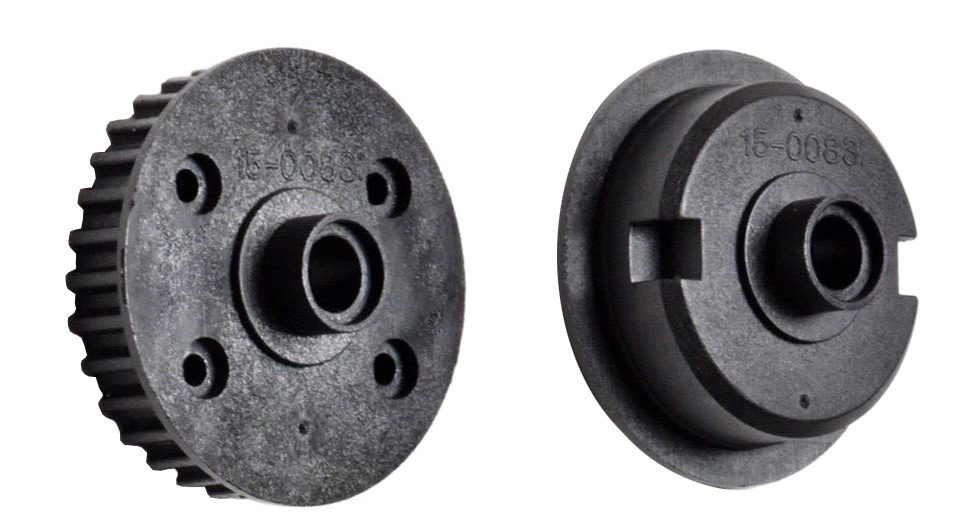

There are actually 3 versions of the LA-1 differential case, which can be recognized as follows:

- Original version without o-ring recess

- Revision with o-ring recess

- Revision with o-ring recess and marked 15-0083 on the cases

The differentials get slightly thinner on each revision (by around 0.4mm each time) if you measure the total width, to allow for the o-ring.

The revisions with recess allow for using 4.5mm o-rings on the outdrives that are 1mm thick. The part number for these is Kyosho ORG045S.

Upgrading with rere internals

While it is possible to modify the original case to take the new OT-222 and OT-224 parts this is a bit of a hassle and not easy to do without eg. a lathe. You would have to modify the small flange and bearing carrying part on the case to allow for the outdrives to penetrate the case enough to fit the pin through the outdrive axle.

The newer LA-1 cases with o-ring recess allow for the OT-224 to go deep enough without modification, not using the shim that comes with the gears. You can then use the OT-222 gears without any further modifications necessary. These gears are made with a different manufacturing process which makes them less notchy when using thick oil, or even differential putty.

I have made a separate post of the cases being built with rere parts. Bear in mind the end result will be not as wide as a normal LA-1 differential, so without spacers you may experience the differential not being centered firmly in the gearbox, with the outdrives in a slightly more inward position.